Bioplastic materials

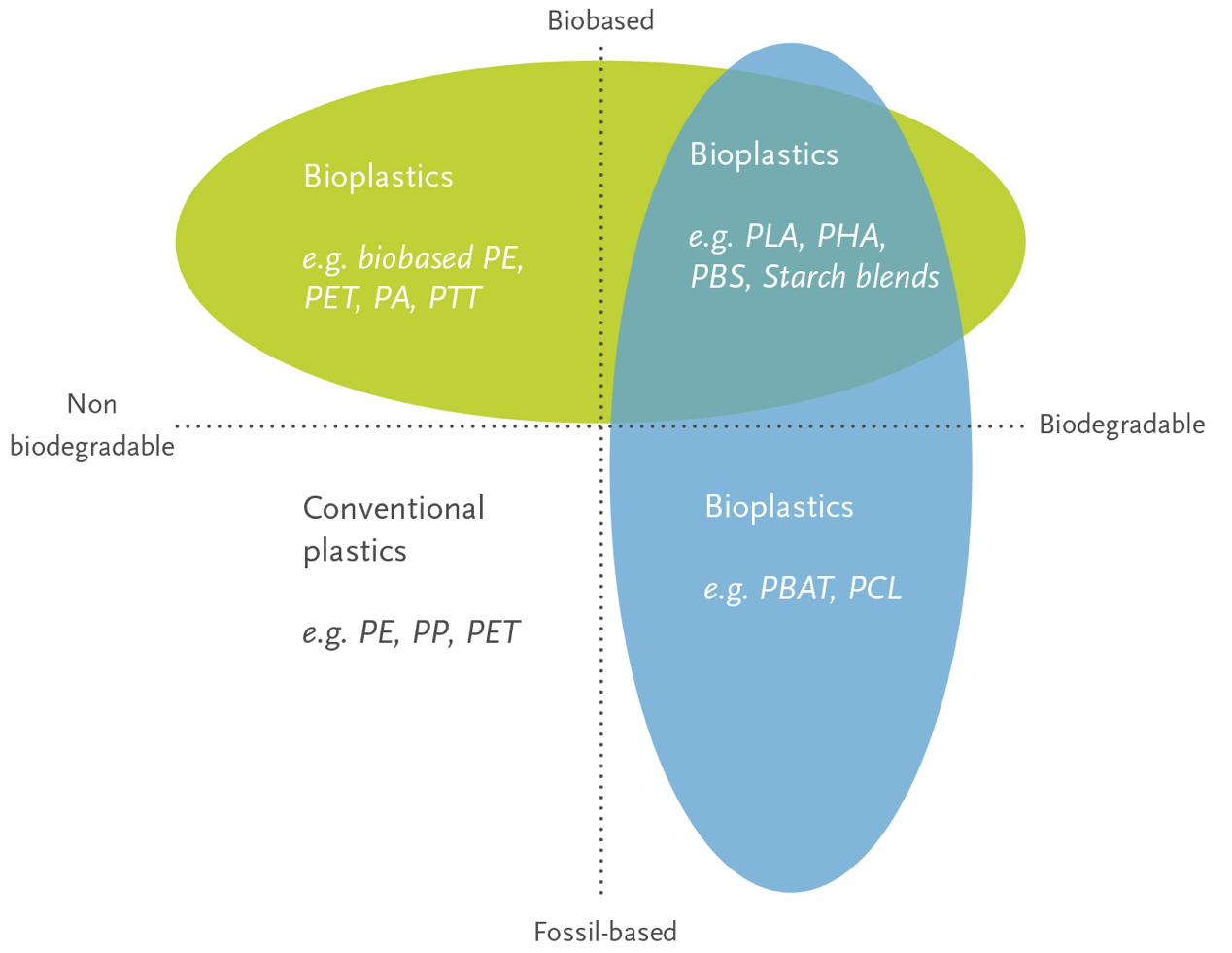

Today, there is a bioplastic alternative for almost every conventional plastic material and corresponding application. Bioplastics – plastics that are biobased, biodegradable, or both – have the same properties as conventional plastics and, in many cases, even offer additional advantages. This includes a reduced carbon footprint or additional waste management options, such as composting. Bioplastics are an essential part of the bioeconomy and a fast-growing, innovative industry that has the potential to decouple economic growth from resource depletion and environmental impact. Bioplastics are a diverse family of materials with differing properties. There are three main groups:

- Bio-based or partially bio-based non-biodegradable plastics, such as bio-based PE, PP, or PET (so-called drop-ins) and bio-based technical performance polymers, such as PTT or TPC-ET;

- Plastics that are both bio-based and biodegradable, such as PLA and PHA or PBS;

- Plastics that are based on fossil resources and are biodegradable, such as PBAT.

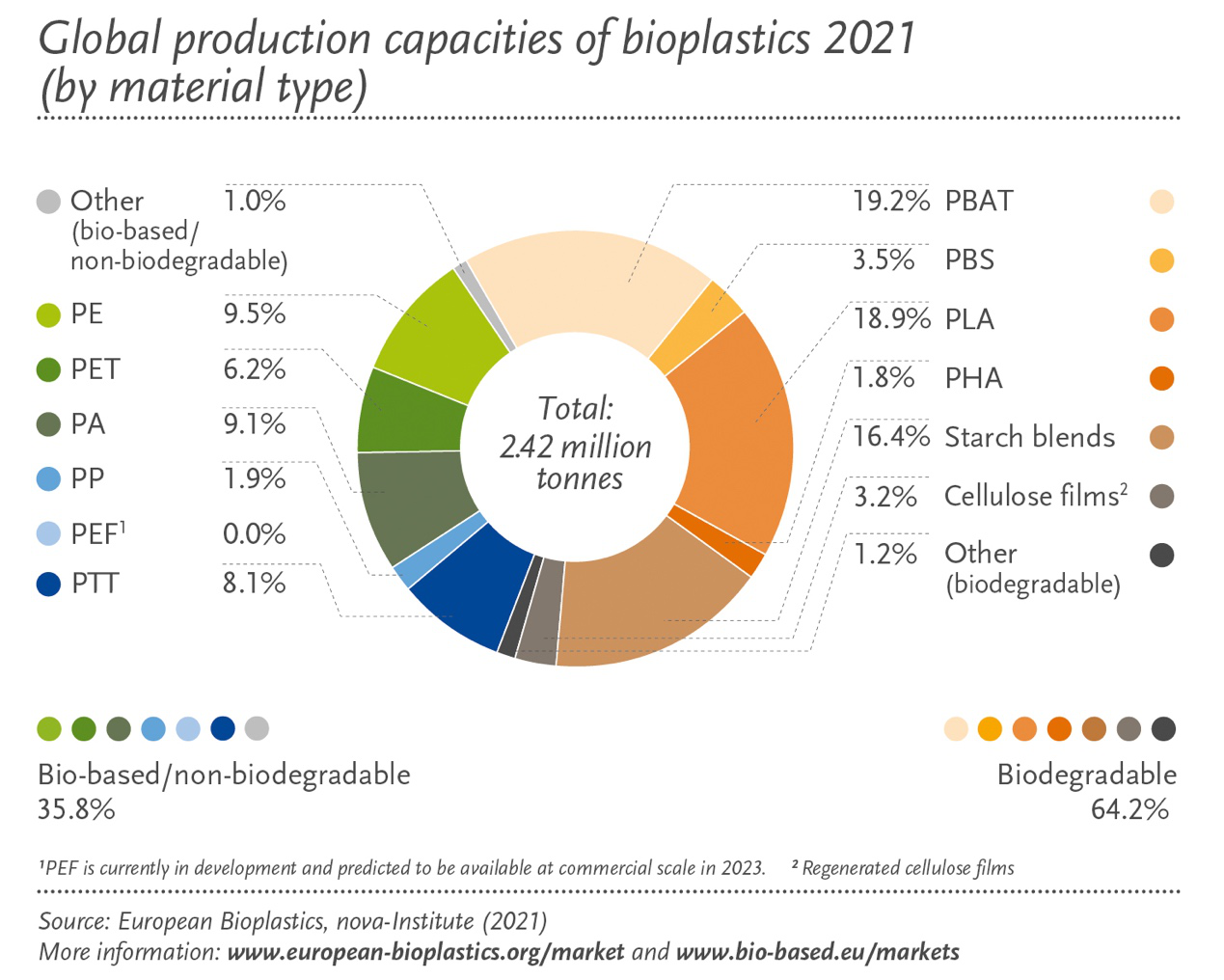

Currently, bioplastics represent about one per cent of the about 367 million tonnes of plastic produced annually. But as demand is rising, and with more sophisticated materials, applications, and products emerging, the market is already growing very dynamically.

Material properties

Bio-based or partially bio-based durable plastics, such as bio-based or partially bio-based PE, PP, PET or PVC, possess properties which are identical to their conventional versions. These bioplastics are technically equivalent to their fossil counterparts; yet, they help to reduce a product’s carbon footprint. Moreover, they can be mechanically recycled in existing recycling streams.

Find out more about bio-based plastics here.

Additionally, new materials, such as PLA, PHA, cellulose or starch-based materials offer solutions with completely new functionalities, such as compostability and in some cases optimised barrier properties. Find out more about biodegradable plastics here. Along with the growth in variety of bioplastic materials, properties, such as flexibility, durability, printability, transparency, barrier, heat resistance, gloss and many more have been significantly enhanced.

Accurate claims and labels ensure clarity and trust: Environmental claims of bioplastics materials and products, such as biodegradability and the amount of biomass content, must always be specific, accurate, and ideally provide a third party substantiation for these claims. A label awarded in accordance with independent certification based on acknowledged standards guarantees that the product fulfills the criteria claimed. As non-experts cannot distinguish bioplastics from conventional plastics, reliable certification and labeling based on approved standards provided by CEN, ASTM, or ISO help the consumer to identify these products and inform about additional qualities the material or product possesses. For more information on relevant standards, certificates, and labels, European Bioplastics has compiled a comprehensive Environmental Communications Guide providing general recommendations as well as specific guidelines for communicating environmental claims for bioplastics.

Recommended articles

-

Photo © iStockphoto.com/baona REPUBLISH July 16, 2019 — Have you ever stood in front of a supermarket shelf and wondered if you should buy that product made from bioplastics rather than the conventional kind? Many people assume all bioplastics are made from plants and can break down completely in the environment. But that’s not the case. The term “bioplastics” is actually used for two separate things: bio-based plastics (plastics made at least partly from biological matter) and biodegradable plastics (plastics that can be completely broken down by microbes in a reasonable timeframe, given specific conditions). Not all bio-based plastics are biodegradable, and not all biodegradable plastics are bio-based. And even biodegradable plastics might not biodegrade in every environment. Sounds confusing? It certainly is...

-

A worker examines plastic bottles at a recycling center in Santiago, Chile. MARTIN BERNETTI/AFP VIA GETTY IMAGES Bioplastics are being touted by industry marketers as the solution to plastics pollution. But the idea that bottles and packaging made of plant-based material can simply be discarded and then break down and disappear is false – recycling and reuse are the only strategies that can work. Coca-Cola calls it the PlantBottle — a new kind of recyclable plastic container, 30 percent of which is made from sugar cane and other plants, with the remaining 70 percent made from traditional oil-based plastic. The company says that PlantBottle packaging now accounts for nearly a third of its North American bottle volume and seven percent globally. Does the PlantBottle mean the giant soft drink company has crack...

-

Bioplastic could be the solution to the growing accumulation of hydrocarbon-derived plastics. These 11 examples could be the future of plastic. 1, 2 With reports of growing amounts of plastic accumulating in the Earth's oceans, not to mention landfills, there is a real need for some form of biodegradable alternative. This is where bioplastics come into their own. Since they are made from natural raw materials they are also able to be degraded by nature, in some cases literally eaten - by you. The following 13 bioplastic solutions could replace regular hydrocarbon derived plastics in the not too distant future. This list is in no particular order and is far from exhaustive. 1、Bio-Plastic Can Now Be Made From Sugar and CO2 Scientists from the Centre of Sustainable Chemical Technologies (CSCT) at the University of Bath ...