Confusion among terms like bioplastics, bio-based and biodegradable plastics makes it hard to discern — and make — the environmentally responsible choice.

Photo © iStockphoto.com/baona

REPUBLISH

July 16, 2019 — Have you ever stood in front of a supermarket shelf and wondered if you should buy that product made from bioplastics rather than the conventional kind? Many people assume all bioplastics are made from plants and can break down completely in the environment. But that’s not the case.

The term “bioplastics” is actually used for two separate things: bio-based plastics (plastics made at least partly from biological matter) and biodegradable plastics (plastics that can be completely broken down by microbes in a reasonable timeframe, given specific conditions). Not all bio-based plastics are biodegradable, and not all biodegradable plastics are bio-based. And even biodegradable plastics might not biodegrade in every environment. Sounds confusing? It certainly is.

“There are a lot of bioplastics or materials that are called bioplastics that are not biodegradable,” says Constance Ißbrücker, head of environmental affairs at the industry association European Bioplastics.

For some plastics, the same polymer chains can be made from renewable sources. The resulting bioplastics are chemically identical to their fossil counterparts. PET, for example — short for polyethylene terephthalate, which is the stuff most bottles are made of — can be synthesized from fossil fuel products or plants like sugarcane. The resulting material is the exact same. Such non-biodegradable bioplastics behave in the environment just like conventional plastic and persist for an unknown but long amount of time.

Bio-Based but not biodegradablePlastics are long polymer chains that can be molded under heat or pressure into almost any shape. They are usually mixed with additives that give the products properties such as durability, flexibility or color. Since mass production started in the second half of the 20th century, the raw material for plastics has mainly been oil and gas.For some plastics, the same polymer chains can be made from renewable sources. The resulting bioplastics are chemically identical to their fossil counterparts. PET, for example — short for polyethylene terephthalate, which is the stuff most bottles are made of — can be synthesized from fossil fuel products or plants like sugarcane. The resulting material is the exact same.Replacing fossil feedstock with renewables can reduce carbon emissions from the raw material. But when it comes to the end of their life, non-biodegradable bioplastics behave in the environment just like conventional plastic — and persist for an unknown but long amount of time.

Not only that, but none of the standards for plastics labeled as biodegradable or compostable today makes them suitable for disposal in the open environment. Given that, can bioplastics play a role in tackling environmental problems? Or are they merely greenwashing? The most accurate answer is, it depends.

PLA: Conditionally Compostable

Take polylactic acid (PLA), for example. This bioplastic is used to make shopping bags, transparent cups, 3-D printing material and other products. Because it can be derived from plant material like corn sugar, potato or sugarcane, it can reduce the demand for fossil fuels used to make conventional plastics.

PLA is recyclable, biodegradable and compostable. But that doesn’t mean the ocean — or any other natural environment — can easily handle it.

To Frederik Wurm, a chemist at the Max Planck Institute for Polymer Research (MPIP), drinking straws made from PLA are “the perfect example for greenwashing.” They are more expensive than other plastic drinking straws, but don’t readily biodegrade on a beach or in the sea.

“You put it on the package [that it] is biodegradable, but at the point where these materials are . . . fear[ed] to end up, they will not biodegrade,” Wurm says.

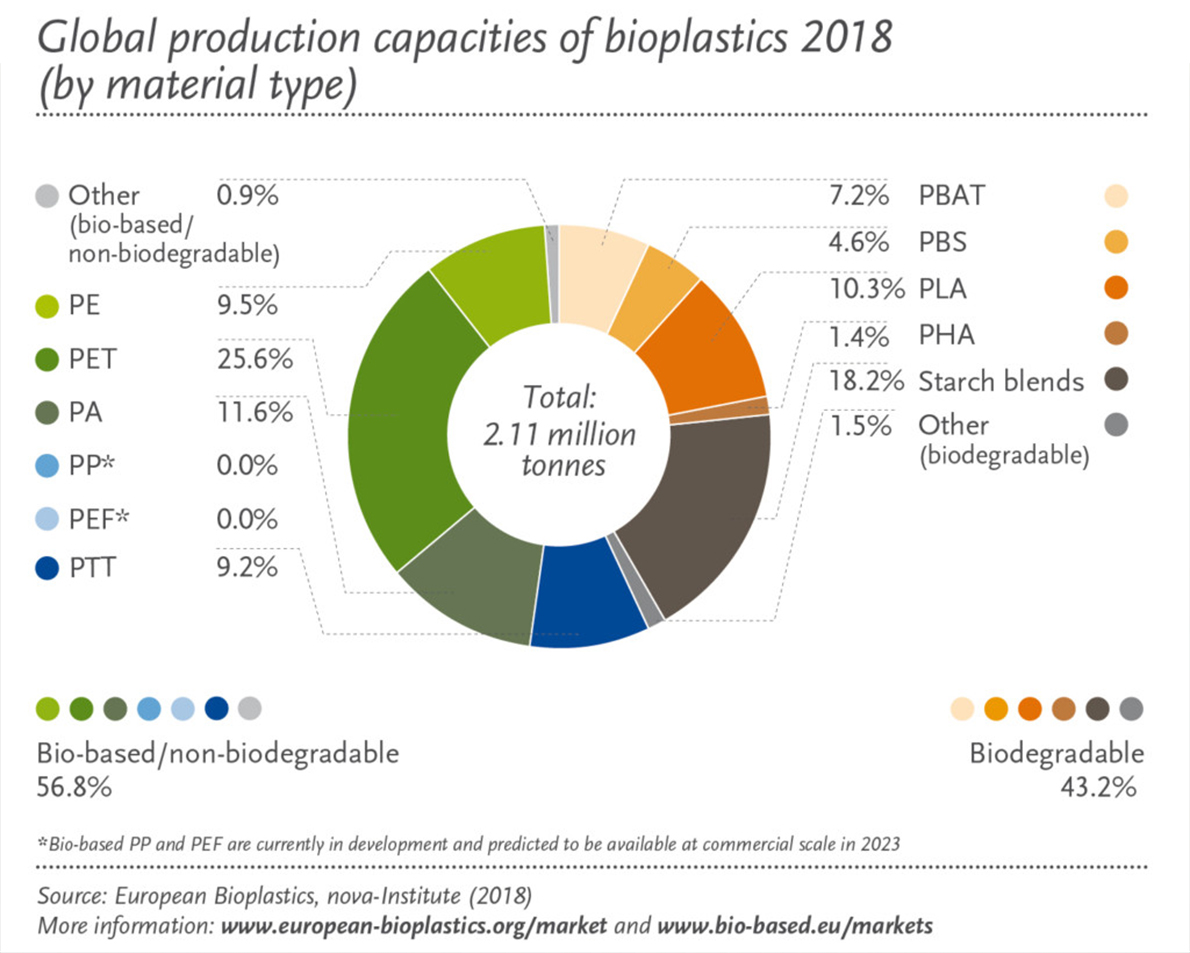

Graphic courtesy of European Bioplastics, Nova-Institute (2018). Click to enlarge.

For biodegradation, PLA needs industrial composting conditions, including temperatures above 58 °C (136 °F). It needs to be properly managed and routed to specialized industrial composting or recycling facilities. Under the right circumstances, microbes can turn the material into carbon dioxide and water within a couple of weeks. However, if it becomes littered or dumped, PLA sticks around for much longer. When pure PLA ends up in seawater, it does not seem to biodegrade at all.

PHA: It’s Complicated

Other kinds of bioplastics are known to better biodegrade in marine environments. However, whether that really happens in a specific case, and how long it will take, is highly unpredictable.

It’s about time — and placeFrom beaches to shallow waters to the open ocean and the deep sea, from the tropics to temperate waters to the Arctic, conditions in the oceans can be multifold. Some habitats are warm, some ice-cold, some light, some dark, some saltier and others less. Each ecosystem is inhabited by different organisms, including the microbes that might or might not be able to break down the plastics. Similarly, soils, rivers and lakes can also offer a variety of conditions.The amount of time it takes for a biodegradable plastic to degrade (and whether it ever degrades) depends on conditions. This is why claiming that a material is biodegradable in the natural environment is so problematic. You never know where it will end up.And how fast would a plastic product need to fully biodegrade without causing harm in the environment around it? A turtle could choke on a bioplastic bag the moment this bag is blown into the sea. Harm can happen right away. So biodegradable plastics are not a license to litter.

Marine biologist Christian Lott and his colleagues at HYDRA, a private research institute with a research station on the Italian island of Elba, have field-tested different biopolymers in a range of aquatic environments from tropical beaches to the Mediterranean seafloor. They found that materials that had been shown to biodegrade in seawater in lab testing also do so in the environmental conditions they tested.

Among the materials tested at HYDRA are bioplastics called polyhydroxyalkanoates (PHAs). Produced by microbes, PHAs currently comprise a tiny slice of the market. However, demand is expected to grow strongly in the next few years.

A thin film of PHA will degrade in a tropical environment on the seafloor in one to two months, Lott says. But in the Mediterranean, it can take 10 times as long. “And imagine, in the Arctic, in the ice or at ice-cold water, or in the deep sea where we have 0 to 4 degrees, hardly any nutrients around, bacteria will have a hard time to digest these materials,” he says.

This is the caveat to PHAs, says Linda Amaral-Zettler, a marine microbiologist at the Royal Netherlands Institute for Sea Research (NIOZ). “While they canbiodegrade in the marine environment, we still need to appreciate that part of the marine environment is not compatible with biodegradation.”

In some regions of the ocean biodegradation is so slow that even organic material like fish or algae can leave their traces in the fossil record.

“Life is complicated,” Lott puts it, “and it’s about life — because it’s bio-degradation.”

Super-Biodegradable?

Even with the best waste management systems, it’s realistic to assume some plastic will always escape. Think of the abrasion from car or bike tires, from ship paints, sneakers, or synthetic garments. If bits of plastics are small enough to travel through the air, they will be hard to ever contain.

So could we design a plastic that breaks down pretty much anywhere?

Wurm says it would theoretically be possible to build molecular triggers into materials so that they know when to biodegrade. “It sounds fancy, and it is fancy and it’s expensive,” he says. But even if the funding were there, finding and including molecular triggers for each and every material in each and every environment seems to be a nearly impossible task.

Single use utensils made of bioplastics are often touted as the environmentally friendly alternative. But not every bioplastic is biodegradable, and most biodegradable plastic only biodegrades under very special conditions. Photo © iStockphoto.com | Whity2j

A material that has a full functionality but biodegrades immediately at its end of life, is “not going to happen. Never,” Lott says.

Different Chemicals, Different Problems

Moreover, when considering the impacts of plastic products on humans and the environment, looking at just the plastic itself is never enough. A single plastic product can contain dozens of chemicals, some of which might have adverse effects on us humans or other organisms if they are released into the environment and taken up.

Lisa Zimmerman, a Ph.D. student in the Department Aquatic Ecotoxicology at Goethe University in Frankfurt (Main), Germany, has conducted research that suggests that chemical mixtures present in biodegradable or bio-based plastic products can influence the metabolic activity of the bioluminescent bacterium Aliivibrio fischeri. In a number of additional experiments she found that these chemical mixtures can have the potential to cause oxidative stress or influence the hormonal system in living organisms.

“What I can tell from my research is that bioplastics are not necessarily safer than conventional plastics with regard to the toxicity of the chemical mixtures they include,” Zimmermann says.

Land Use Issues

Bio-based plastics have other environmental implications as well. One big criticism has been the land needed to grow the plants.

On the basis of a report from the Institute for Bioplastics and Biocomposites (IfBB) in Hanover, European Bioplastics estimates that bio-based plastics currently use less than 0.02% of agricultural land. “There is no real competition with food and feed production,” Ißbrücker argues.

But Christoph Lauwigi, who represents the working group on waste and resources with Friends of the Earth Germany (BUND) worries about the side effects of a growth in the bioplastic market. In the German Plastic Atlas, he explains that an increase in bio-based plastics could raise the pressure on arable land, potentially leading to water shortages, desertification and the loss of habitats and biodiversity. He also notes that the reliance on industrial agriculture for the production of new plastics might increase monoculture cropping and the use of pesticides.

One criticism of bio-based plastics is that they increase pressure on arable land. But scientists are searching for feedstocks that might be more environmentally friendly than conventional crops, such as waste materials or algae. Photo © iStockphoto.com | stevanovicigor

Ißbrücker says the industry is working toward a smaller land use footprint by using waste materials or algae. At this point however, these sources cannot be processed as effectively yet as the current feedstocks, she adds.

Niche Applications

Plastics that are currently marketed as “biodegradable” will themselves contribute to plastic pollution if they are lost or littered. They do not break down as quickly and completely in the environment as the term might imply and can thus harm wildlife and ecosystems. But there are a few applications where using biodegradable plastics may provide a net benefit to the environment.

In some countries, bags that are compostable under industrial conditions are used to collect organic waste. They can offer a cleaner and more convenient way than nondisposable containers for people to collect food scraps for composting.

Enzo Favoino, a waste management expert at the Scuola Agraria del Parco di Monza in Italy and chair of the Scientific Committee of Zero Waste Europe, is convinced this is the way to go. Fewer organics in the trash means less fermentation, allowing waste management operators to come by less often to pick up the trash. This can not only save money but also boost the recycling rates of other materials such as paper, glass, plastic and metal, he says.

Collecting organic waste separately also diverts food scraps from landfills and dumps, where they can produce methane — a powerful greenhouse gas contributing to climate change.

Bioplastics can be an improvement over conventional plastics for mulching crops but are not without challenges of their own. Photo © iStockphoto.com | TonyFreedom

However, not every country has the infrastructure in place to use compostable bags to these ends. In Germany, for example, compostable bags are screened out of the organics by technology that doesn’t distinguish between compostable and conventional plastic.

Biodegradable plastics are currently also marketed as mulching films for agriculture, which farmers can just leave on the fields to plow under. For decades, plastic mulch film has been spread out on fields to support crop growth and save pesticides and water. But with conventional plastics this so-called Plasticulturecan cause “white pollution” to accumulate on farmland if it is not removed and discarded.

Is biodegradable film a safe alternative? If they are proven to biodegrade in the soil, they would leave less pollution behind. But wind or animals might carry pieces of broken film into the air, rivers or oceans, to places where they might not be able to biodegrade. There’s also a potential for chemicals to leach from the films to the soil ecosystem, a question that is currently under scrutiny.

Tackling Confusion

There’s no doubt, bioplastics are still plastics. Just because some of them are made from plants or have the potential to biodegrade under limited conditions, they can’t be touted as “planet-safe.” For the ones that claim to biodegrade or compost, the fine print is crucial.

The planet’s most important stories — delivered to your inbox

Be the first to hear about important new environmental stories. Sign up now to receive our newsletter.

窗体顶端

SUBSCRIBE

窗体底端

So check the label: What does it say? Where and how is it supposed to biodegrade? How can you safely dispose of the product? 5 Gyres, a California-based nonprofit working on plastic pollution, has published an overview of labels in its Better Alternatives Now B.A.N. List 2.0. Beware, however: According to Ißbrücker, some uses of labels are fake.

Finally, be cautious when you read that a material is oxo-biodegradable. These are conventional plastics like polyethylene mixed with metal compounds that make them fall apart faster. According to a report by the United Nations Environment Programme (UNEP), it hasn’t been proven that they truly biodegrade, and it is feared they might just accelerate microplastic pollution. Similarly, European Bioplastics warn that so-called “enzyme-mediated degradable plastics” aren’t truly biodegradable.

Reduction Remains Key

The plastic industry projects strong growth in production, while many environmentalists are calling to reduce use.

Biodegradable plastics won’t solve the plastic crisis, so tackling consumption remains key. “By just reducing the amounts and the types of different packaging that we have in our supermarkets, we can do a lot, without developing novel materials,” says Wurm.

Even European Bioplastics’ Ißbrücker thinks that might very well happen. “Maybe not in 5 or 10 years, but as the problems keep growing, plastic production might go down one day, because it’s just too much.”

Recommended articles

-

A worker examines plastic bottles at a recycling center in Santiago, Chile. MARTIN BERNETTI/AFP VIA GETTY IMAGES Bioplastics are being touted by industry marketers as the solution to plastics pollution. But the idea that bottles and packaging made of plant-based material can simply be discarded and then break down and disappear is false – recycling and reuse are the only strategies that can work. Coca-Cola calls it the PlantBottle — a new kind of recyclable plastic container, 30 percent of which is made from sugar cane and other plants, with the remaining 70 percent made from traditional oil-based plastic. The company says that PlantBottle packaging now accounts for nearly a third of its North American bottle volume and seven percent globally. Does the PlantBottle mean the giant soft drink company has crack...

-

Today, there is a bioplastic alternative for almost every conventional plastic material and corresponding application. Bioplastics – plastics that are biobased, biodegradable, or both – have the same properties as conventional plastics and, in many cases, even offer additional advantages. This includes a reduced carbon footprint or additional waste management options, such as composting. Bioplastics are an essential part of the bioeconomy and a fast-growing, innovative industry that has the potential to decouple economic growth from resource depletion and environmental impact. Bioplastics are a diverse family of materials with differing properties. There are three main groups: Bio-based or partially bio-based non-biodegradable plastics, such as bio-based PE, PP, or PET (so-called drop-ins) and bio-based technical performance polymers, such as PTT or TPC-E...

-

Bioplastic could be the solution to the growing accumulation of hydrocarbon-derived plastics. These 11 examples could be the future of plastic. 1, 2 With reports of growing amounts of plastic accumulating in the Earth's oceans, not to mention landfills, there is a real need for some form of biodegradable alternative. This is where bioplastics come into their own. Since they are made from natural raw materials they are also able to be degraded by nature, in some cases literally eaten - by you. The following 13 bioplastic solutions could replace regular hydrocarbon derived plastics in the not too distant future. This list is in no particular order and is far from exhaustive. 1、Bio-Plastic Can Now Be Made From Sugar and CO2 Scientists from the Centre of Sustainable Chemical Technologies (CSCT) at the University of Bath ...